Synthetic terminal web, rope net

●Features

The synthetic terminal web (nylon Tetoron polyethylene polyester) tolerates chemicals, and a slightly strong thing becomes the characteristic in the use.

Sieve (sieve) efficiency (or filtration efficiency) is good, and there is not blocking, and scale of mesh is exact, and there is not waterproofing, absorbency and is noncorrosive, and, as clutches, the electricity insulation characteristics do not forgive a metal mesh product, the following of other nets.

The synthetic terminal web (nylon Tetoron polyethylene polyester) tolerates chemicals, and a slightly strong thing becomes the characteristic in the use.

Sieve (sieve) efficiency (or filtration efficiency) is good, and there is not blocking, and scale of mesh is exact, and there is not waterproofing, absorbency and is noncorrosive, and, as clutches, the electricity insulation characteristics do not forgive a metal mesh product, the following of other nets.

●Filter cross (mesh textile product)

Organization | |

Flat | Powerful net, silk (NP) to nip (nylon), Powerful net to nip (polyester), Powerful net to nip (polyethylene), Nylon N, NB, Tetoron TM, TB, nairomborudingukurosu NMG (flat specially) |

Intricate design | Special net to nip (polyethylene), PP special texture, borutingukurosu NXXX |

hammoji ri | nairomborutingukurosu NXXX |

somoji ri | nairomborutingukurosu GG.NGG |

Kind | |

Silk | 220 mesh - 15 mesh |

Intricate design nylon | 508 mesh - 8 mesh and various special textures |

Tetoron | 508 mesh - 8 mesh and various special textures |

| Polyethylene | 200 - 5 and various special textures |

Polypropylene | Mesh screen |

Polyester | 70 mesh - 15 mesh and various special textures |

Mesh cross network (synthetic terminal web)

Polyethylene |

※*shufuku accepts it about the special specifications product. Please consult. In addition, the thing with the "*" in a table seal becomes the build-to-order manufacturing. |

●Strong net standard list to nip (polyethylene)

Article number | kikakufuku (cm) | Winding (m) | Mesh 2.54cm | Opening

(μm) | Opening

Area (%) | Line diameter (μm) |

200 | 102 | 50 | 156/100 | 112 | 32 | 86 |

180 | 102 | 50 | 144/100 | 122 | 34 | 86 |

160 * | 102 | 50 | 130/100 | 135 | 37 | 86 |

150 | 102 | 50 | 120/102 | 143 | 39 | 86 |

140 | 102 | 50 | 112/90 | 155 | 38 | 86/106 |

120 | 102 | 50 | 96/76 | 181 | 38 | 106/122 |

100 | 102 | 50 | 83/64 | 224 | 42 | 122 |

80 | 102 | 50 | 67/61 | 261 | 43 | 122/150 |

70 | 102 | 50 | 59/56 | 292 | 44 | 150 |

60 | 102 | 50 | 50/47 | 351 | 45 | 173 |

50 | 102 | 50 | 42/40 | 407 | 43 | 212 |

40 | 102 | 50 | 34/32 | 526 | 47 | 244 |

30 | 102 | 50 | 25/23 | 760 | 52 | 298 |

24 | 102 | 50 | 20 | 925 | 53 | 345 |

18 | 102 | 50 | 16 | 1,242 | 61 | 345 |

14 | 102 | 50 | 12 | 1,572 | 55 | 545 |

Eight | 102 | 50 | 7 | 3,083 | 72 | 545 |

Five | 102 | 50 | 5 | 4,310 | 72 | 770 |

●Special texture standard list to nip (polyethylene)

Article number | kikakufuku (cm) | Winding (m) | Mesh 2.54cm | Fineness (D) | Organization |

ET 9435 | 92.121 | 50 | 89/35 | 500 | Herringbone weaving |

ET 6227 | 92.121 | 30 | 62/27 | 1,000 | Herringbone weaving |

ET 2022 | 106 | 30 | 20/22 | 2,000 | Herringbone weaving |

ET 6243 | 130 | 50 | 62/43 | 600/400 | Twill fabrics |

EPMT 16445 | 99 | 50 | 164/45 | 200/170 | Twill fabrics |

EP 19440 | 92 | 30 | 194/40 | 100/150 | Twill fabrics |

Polypropylene |

※*shufuku accepts it about the special specifications product. Please consult. In addition, the thing with the "*" in a table seal becomes the build-to-order manufacturing. |

●Strong net standard list to nip (polypropylene)

Article number | kikakufuku

(cm) | Winding

(m) | Mesh

2.54cm | Opening

(μm) | Opening

Area (%) | Line diameter

(μm) |

200 * | 102 | 50 | 156/100 | 113 | 32 | 87 |

150 * | 102 | 50 | 120/102 | 142 | 39 | 87 |

100 * | 102 | 50 | 83/64 | 222 | 42 | 125 |

70 | 102 | 50 | 59/56 | 289 | 44 | 153 |

50 | 102 | 50 | 42/40 | 444 | 43 | 176 |

30 | 102 | 50 | 25/23 | 754 | 52 | 305 |

24 | 102 | 50 | 20/20 | 965 | 53 | 305 |

18 | 92 | 50 | 16/16 | 1,194 | 61 | 394 |

14 | 92 | 50 | 12/12 | 1,723 | 55 | 594 |

Nylon 1 |

※*shufuku accepts it about the special specifications product. Please consult. In addition, the thing with the "*" in a table seal becomes the build-to-order manufacturing. |

●NXX standard list

Article number | kikakufuku (cm) | Winding (m) | Mesh 2.54cm | Opening (μm) | Opening Area (%) | Line diameter (μm) |

NXXX 25 | 120 | 30 | 200 | 41 | 10 | 43.43/

43.43 |

NXX 25 | 102 | 30 | 198/240 | 63 | 30 | 43.43/43 |

NXX 18 | 107 | 30 | 190/224 | 65 | 27 | 43.50/50 |

NXX 17 | 107 | 30 | 180/209 | 72 | 30 | 43.50/50 |

NXX 16 | 120 | 30 | 174/208 | 75 | 32 | 43.50/50 |

NXX 15 | 120 | 30 | 165/190 | 85 | 35 | 43.50/50 |

NXX 14 | 135 | 30 | 158/172 | 95 | 38 | 43.50/50 |

NXX 13 | 135 | 30 | 148/156 | 100 | 36 | 43.61/61 |

NXX 12

1/2 | 120 | 30 | 142/152 | 106 | 37 | 43.61/61 |

NXX 12 | 135 | 30 | 137/147 | 112 | 39 | 43.61/61 |

NXX 11 | 135 | 30 | 133/141 | 118 | 41 | 43.61/61 |

NXX 10

1/2 | 120 | 30 | 128/136 | 125 | 42 | 43.61/61 |

NXX 10 | 135 | 30 | 121/130 | 132 | 42 | 50.61/61 |

NXX 9

1/2 | 120 | 30 | 115/127 | 140 | 44 | 50.61/61 |

NXX 9 | 135 | 30 | 108/115 | 150 | 43 | 50.70/70 |

NXX 8

1/2 | 120 | 30 | 104/110 | 160 | 45 | 50.70/70 |

NXX 8 | 135 | 30 | 90.5/101.5 | 180 | 46 | 61.80/70 |

NXX 7 | 135 | 30 | 84.5/91 | 200 | 48 | 61.80/70 |

●NMG standard list

Article number | kikakufuku

(cm) | Winding (m) | Mesh

2.54cm | Opening (μm) | Opening Area (%) | Line diameter (μm) |

NMG 84 | 120 | 30 | 79.5 | 200 | 39 | 120 |

NMG 72 | 120 | 30 | 74 | 224 | 43 | 120 |

NMG 70 | 120 | 30 | 70.0 | 236 | 42 | 130 |

NMG 68 | 120 | 30 | 68.5 | 243 | 43 | 130 |

NMG 66 | 120 | 30 | 67.5 | 250 | 44 | 130 |

NMG 64 | 120 | 30 | 61.0 | 265 | 41 | 150 |

NMG 62 | 120 | 30 | 59.5 | 275 | 42 | 150 |

NMG 60 | 120 | 30 | 59.0 | 280 | 42 | 150 |

NMG 58 | 120 | 30 | 56.5 | 300 | 45 | 150 |

NMG 56 | 120 | 30 | 53.5 | 308 | 42 | 165 |

NMG 54 | 120 | 30 | 53.0 | 315 | 43 | 165 |

NMG 52 | 120 | 30 | 50.5 | 335 | 44 | 165 |

NMG 50 | 120 | 30 | 49.0 | 355 | 47 | 165 |

NMG 48 | 120 | 30 | 47.0 | 363 | 45 | 180 |

NMG 47 | 120 | 30 | 44.0 | 375 | 42 | 200 |

NMG 46 | 120 | 30 | 44.5 | 390 | 47 | 180 |

NMG 45 | 120 | 30 | 42.5 | 400 | 45 | 200 |

NMG 44 | 120 | 30 | 40.5 | 425 | 46 | 200 |

NMG 42 | 120 | 30 | 38.0 | 450 | 45 | 220 |

NMG 40 | 120 | 30 | 36.5 | 475 | 47 | 220 |

NMG 38 | 120 | 30 | 35.5 | 500 | 49 | 220 |

NMG 36 | 120 | 30 | 34.0 | 530 | 50 | 220 |

NMG 34 | 120 | 30 | 31.5 | 560 | 48 | 250 |

NMG 32 | 120 | 30 | 30.0 | 600 | 50 | 250 |

NMG 31 | 120 | 30 | 29.0 | 630 | 52 | 250 |

NMG 30 | 120 | 30 | 27.5 | 670 | 53 | 250 |

NMG 28 | 120 | 30 | 25.5 | 710 | 51 | 280 |

NMG 27 | 120 | 30 | 24.5 | 750 | 52 | 280 |

NMG 26 | 120 | 30 | 23.5 | 800 | 55 | 280 |

NMG 24 | 120 | 30 | 21.0 | 850 | 49 | 350 |

NMG 23 | 120 | 30 | 20.5 | 900 | 53 | 350 |

NMG 20 | 120 | 30 | 19.0 | 1,000 | 56 | 350 |

NMG 19 | 120 | 30 | 16.5 | 1,120 | 53 | 430 |

NMG 17 | 120 | 30 | 15.0 | 1,250 | 54 | 430 |

NMG 15 | 120 | 30 | 14.0 | 1,400 | 60 | 430 |

NMG 14 | 120 | 30 | 12.0 | 1,600 | 57 | 500 |

NMG 12 | 120 | 30 | 11.0 | 1,800 | 61 | 500 |

NMG 10 | 120 | 30 | 9.5 | 2,000 | 56 | 670 |

Nylon 2 |

※*shufuku accepts it about the special specifications product. Please consult. In addition, the thing with the "*" in a table seal becomes the build-to-order manufacturing. |

●NB standard list

Article number | kikakufuku (cm) | Winding

(m) | Mesh

2.54cm | Opening (μm) | Opening Area (%) | Line diameter (μm) | Thickness (μm) |

NB 90* | 102 | 50 | 90 | 155 | 30 | 130 | 270 |

NB 80 | 102 | 50 | 80 | 190 | 36 | 130 | 240 |

NB 60 | 102 | 50 | 60 | 258 | 37 | 165 | 320 |

NB 50 | 102 | 50 | 50 | 308 | 37 | 200 | 380 |

NB 40 | 102 | 50 | 40 | 435 | 47 | 200 | 380 |

NB 34 | 102 | 50 | 34 | 512 | 47 | 235 | 440 |

NB 20 | 102 | 50 | 20 | 990 | 61 | 280 | 520 |

●N-NO standard list (◎= intricate design organization)

Article number | kikakufuku (cm) | Winding (m) | Mesh

2.54cm | Opening

(μm) | Opening

Area (%) | Line diameter (μm) | Thickness (μm) |

N-NO.508S◎ | 115 | 30 | 508 | 20 | 16 | 30 | 60 |

N-NO.460S ◎ * | 115 | 30 | 460 | 25 | 21 | 30 | 60 |

N-NO.420T◎ | 115 | 30 | 420 | 25 | 18 | 35 | 70 |

N-NO.420S ◎ * | 115 | 30 | 420 | 30 | 25 | 30 | 51 |

N-NO.380T◎ | 115 | 30 | 380 | 32 | 23 | 35 | 68 |

N-NO.380S* | 115 | 30 | 380 | 37 | 30 | 30 | 55 |

N-NO.355T◎ | 115 | 30 | 355 | 37 | 26 | 35 | 66 |

N-NO.355S* | 115 | 30 | 355 | 42 | 34 | 30 | 52 |

N-NO.330T◎ | 115 | 30 | 330 | 42 | 30 | 35 | 66 |

N-NO.330S* | 115 | 30 | 330 | 47 | 37 | 30 | 50 |

N-NO.305T | 115 | 30 | 305 | 48 | 34 | 35 | 60 |

N-NO.305S* | 115 | 30 | 305 | 53 | 41 | 30 | 53 |

N-NO.280HD* | 115 | 30 | 280 | 53 | 34 | 38 | 64 |

N-NO.270T | 115 | 30 | 270 | 59 | 39 | 35 | 60 |

N-NO.255HD | 115 | 30 | 255 | 57 | 32 | 43 | 75 |

N-NO.230T | 115 | 30 | 230 | 67 | 37 | 43 | 75 |

N-NO.200HD | 115 | 30 | 200 | 77 | 37 | 50 | 86 |

N-NO.175T | 115 | 30 | 175 | 95 | 43 | 50 | 87 |

N-NO.150T | 115 | 30 | 150 | 108 | 41 | 61 | 106 |

N-NO.125HD* | 115 | 30 | 125 | 123 | 37 | 80 | 142 |

N-NO.125T | 115 | 30 | 125 | 133 | 43 | 70 | 121 |

N-NO.100S | 115 | 30 | 110 | 161 | 49 | 70 | 121 |

Polyester |

※*shufuku accepts it about the special specifications product. Please consult. In addition, the thing with the "*" in a table seal becomes the build-to-order manufacturing. |

●Polyester

Article number | kikakufuku

(cm) | Winding (m) | Mesh

2.54cm | Opening (μm) | Opening

Area (%) | Line diameter (μm) | Thickness (μm) |

TXX 25* | 107 | 50 | 196 | 63 | 23 | 20 | 80 |

TXX 20* | 107 | 50 | 175 | 78 | 29 | 20 | 80 |

TXX 18* | 107 | 50 | 162/165 | 72 | 22 | 30 | 105 |

TXX 16* | 107 | 50 | 148/150 | 87 | 26 | 30 | 105 |

TXX 14* | 107 | 50 | 140/138 | 100 | 30 | 30 | 105 |

TXX 12* | 107 | 50 | 128/124 | 107 | 28 | 40 | 120 |

TXX 10* | 107 | 50 | 110/106 | 140 | 36 | 40 | 120 |

TXX 8* | 107 | 50 | 78/83 | 185 | 34 | 75 | 185 |

TXX 7* | 107 | 50 | 78/72 | 208 | 38 | 75 | 185 |

TXX 6* | 107 | 50 | 70 | 232 | 41 | 75 | 185 |

Article number | kikakufuku

(cm) | Winding

(m) | Mesh

2.54cm | Opening (μm) | Opening Area (%) | Line diameter

(μm) | Thickness (μm) |

TP 230* | 115 | 50 | 204/228 | 58 | 24 | 22/20 | 80 |

TP 200* | 115 | 50 | 204/190 | 71 | 31 | 22/20 | 80 |

TP 180* | 115 | 50 | 180/165 | 90 | 37 | 22/20 | 80 |

TP 160* | 115 | 50 | 160/156 | 103 | 41 | 22/30 | 80 |

TP 150* | 115 | 50 | 150/140 | 109 | 39 | 22/30 | 90 |

TP 135* | 115 | 50 | 135/125 | 130 | 44 | 22/30 | 90 |

TP 120* | 115 | 50 | 120/115 | 150 | 48 | 22/30 | 90 |

TP 100* | 115 | 50 | 109/97 | 192 | 55 | 22/30 | 90 |

TP 90* | 115 | 50 | 90 | 199 | 50 | 30/30 | 100 |

TP 80* | 115 | 50 | 80 | 234 | 55 | 30/30 | 100 |

TP 70* | 115 | 50 | 68 | 291 | 60. | 30/30 | 100 |

TP 60* | 115 | 50 | 60 | 340 | 65 | 30/30 | 100 |

Other mesh |

●Silk

Article number | kikakufuku (cm) | Winding

(m) | Mesh 2.54cm | Opening

(μm) | Opening Area (%) | Fineness

(D) |

NP 75 | 102 | 30 | 156/200 | 77 | 29 | 21/27 |

NP 65 | 102 | 30 | 156/174 | 85 | 30 | 21/27 |

NP 58 | 102 | 30 | 156 | 90 | 3 | 21/27 |

NP 52 | 102 | 30 | 139 | 99 | 129 | 27/27 |

NP 45 | 102 | 30 | 121 | 118 | 32 | 42/42 |

NP 40 | 102 | 30 | 107 | 142 | 36 | 42/42 |

NP 32 | 102 | 30 | 86 | 183 | 38 | 54/54 |

NP 26 | 102 | 30 | 70 | 236 | 42 | 54/54 |

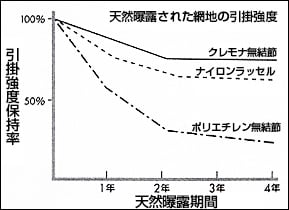

Synthetic fiber rope net (ball-proof net)

Characteristic of the net | |

Nylon | I am very strong in pulling, friction. |

Polyethylene | There is not absorbency, and a color is stable. |

Spider Rena (vinylon) | I am superior in weatherability. |

●Synthetic fiber net performance list

※The data are things of the association of Japanese chemical fiber announcement. | Cremona | Nylon | Polyethylene (low-pressure law) | |||

Filament | Filament | Filament | ||||

Normal | Strong power | Normal | Strong power | |||

It is hikichokyo (g/D) | Standard time | 3.0-4.0 | 6.0-9.5 | 4.8-6.4 | 6.4-9.5 | 5.0-9.0 |

In dampness | 2.1-3.2 | 5.0-8.5 | 4.2-5.9 | 5.9-8.0 | 5.0-9.0 | |

Dryness and moisture strong ratio (%) | 70-80 | 75-90 | 84-92 | 84-92 | 100 | |

Catch strength (g/D) | 4.5-6.0 | 7.0-13.0 | 8.5-11.5 | 10.7-14.3 | 6.2-13.0 | |

Line strength (g/D) which is constipated | 2.2-3.0 | 2.7-5.0 | 4.3-6.0 | 5.4-6.5 | 3.5-5.7 | |

Growth rate (%) | Standard time | 17-22 | 8-22 | 28-45 | 16-25 | 8-35 |

In dampness | 17-25 | 8-26 | 36-52 | 20-30 | 8-35 | |

Tensile coefficient of elasticity (%) (3% tensile rate) | 70-90 | 70-90 | 98-100 | 85-97 | ||

Initial pulling resistance degree (appearance Young's modulus) | (g/D) | 60-90 | 70-250 | 20-45 | 27-50 | 35-100 |

(kg/mm) | 700-950 | 800-2900 | 200-450 | 280-510 | 300-850 | |

Specific gravity | 1.26-1.30 | 1.14 | 0.94-0.96 | |||

Water rate (%) | kotei | 5.0 | 4.5 | 0 | ||

Normal condition 20 degrees Celsius 65% RH | 3.5-4.5 | 3.0-5.0 | 3.0-5.0 | 0 | ||

Other states 20 degrees Celsius 20% RH | ■20%RH

1.2-1.8

■95%RH 10.0-12.0 | ■20%RH

1.0-1.8

■95%RH 8.0-9.0 | ■20%RH

0

■95%RH 0-0.1 | |||

●Diameter, length, strong stretchability of the thread

Thread class | Diameter, length

Strong stretchability | The number | |||||||

15 | 30 | 45 | 60 | 75 | 90 | 120 | 180 | ||

Nylon | Diameter (mm) | 0.85 | 1.20 | 1.50 | 1.70 | 1.90 | 2.10 | 2.40 | 2.70 |

Length /kg | 2,560 | 1,240 | 804 | 620 | 496 | 414 | 310 | 206 | |

Strongly (Inui time kg) | 21.9 | 42.8 | 64.0 | 83.0 | 100.0 | 115.5 | 148.0 | 202.0 | |

Stretchability (Inui time kg) | 29.0 | 35.0 | 38.0 | 40.0 | 42.0 | 44.0 | 45.0 | 46.0 | |

Polyethylene | Diameter (mm) | 1.40 | 1.95 | 2.30 | 2.70 | 2.90 | 3.20 | 3.60 | 4.30 |

Length /kg | 1,250 | 625 | 417 | 313 | 250 | 208 | 156 | 104 | |

Strongly (Inui time kg) | 31.2 | 60.0 | 83.5 | 106.0 | 152.0 | 172.0 | 202.5 | 270.0 | |

Stretchability (Inui time kg) | 25.5 | 30.0 | 31.0 | 32.0 | 33.0 | 34.0 | 35.0 | 36.5 | |

Cremona | Diameter (mm) | 1.00 | 1.50 | 1.80 | 2.10 | 2.30 | 2.50 | 2.90 | 3.60 |

Length /kg | 2,400 | 1,200 | 800 | 600 | 480 | 400 | 300 | 200 | |

Strongly (Inui time kg) | 23.0 | 47.0 | 70.0 | 93.0 | 116.1 | 140.0 | 186.0 | 279.0 | |

Stretchability (Inui time kg) | 19.0 | 19.0 | 19.0 | 19.0 | 19.0 | 19.0 | 19.0 | 19.0 | |

List of net products |

●Ball-proof net 1

Product cord | Fiber name | Thickness of the thread | Scale of mesh | Color | Remarks |

0009 | Nylon | 210D/48 | 25mm | ||

0010 | Nylon | 210D/48 | 25mm | White | |

0041 | Polyester | 250D/30 | 40mm | ||

0600 | Polyester | 365T/56 book | 40mm | Eco | |

0599 | Polyester | 365T/56 book | 40mm | Brown | Eco |

0608 | Polyester | 365T/56 book | 100mm | Eco | |

0597 | Polyester | 1100T/18 book | 40mm | Young bamboo | Eco |

0671 | Polyester | 1100T/18 book | 40mm | Brown | |

0057 | Cremona | 500D/40 | 37.5mm | ||

0072 | Cremona | 20S/60 book | 110mm | White | Existence is constipated |

0116 | Polyethylene | 400D/22 | 37.5mm | ||

0117 | Polyethylene | 400D/22 | 37.5mm | Silver | |

0144 | Polyethylene | 400D/36 | 25mm | ||

0147 | Polyethylene | 400D/36 | 25mm | Brown | |

0149 | Polyethylene | 400D/36 | 25mm | Silver | |

0150 | Polyethylene | 400D/36 | 25mm | Black | |

0151 | Polyethylene | 400D/36 | 25mm | White | |

0153 | Polyethylene | 400D/36 | 25mm | Blue | |

0156 | Polyethylene | 400D/36 | 25mm | Orange | |

0160 | Polyethylene | 400D/44 | 25mm | ||

0162 | Polyethylene | 400D/44 | 25mm | Silver | |

0169 | Polyethylene | 400D/50 | 25mm | Silver | |

0166 | Polyethylene | 400D/60 | 25mm | ||

0168 | Polyethylene | 400D/44 | 30mm | ||

0124 | Polyethylene | 400D/30 | 25mm | Existence is constipated | |

0177 | Polyethylene | 400D/45 | 37.5mm | Existence is constipated | |

0213 | Polyethylene | 400D/75 | 37.5mm | Existence is constipated | |

0179 | Polyethylene | 400D/44 | 37.5mm | ||

0181 | Polyethylene | 400D/44 | 37.5m | Brown | |

0182 | Polyethylene | 400D/44 | 37.5mm | Silver | |

0183 | Polyethylene | 400D/44 | 37.5mm | White | |

0184 | Polyethylene | 400D/44 | 37.5mm | Black | |

0174 | Polyethylene | 400D/44 | 37.5mm | Yellow | |

0140 | Polyethylene | 400D/48 | 37.5mm | Orange | |

0167 | Polyethylene | 400D/48 | 37.5mm | Blue |

●Ball-proof net 2

Product cord | Fiber name | Thickness of the thread | Scale of mesh | Color | Remarks |

0134 | Polyethylene | 600D/24 | 37.5mm | Powerful thread | |

0331 | Polyethylene | 400D/36 | 40mm | Powerful thread | |

0329 | Polyethylene | 400D/36 | 40mm | Brown | Powerful thread |

0235 | Polyethylene | 400D/36 | 45mm | Powerful thread | |

0266 | Polyethylene | 400D/36 | 45mm | Gray | Powerful thread |

0189 | Polyethylene | 300D/60 | 40mm | ||

0190 | Polyethylene | 300D/60 | 40mm | Brown | |

0199 | Polyethylene | 400D/50 | 50mm | ||

0201 | Polyethylene | 400D/60 | 37.5mm | ||

0202 | Polyethylene | 400D/60 | 37.5mm | Silver | |

0269 | Polyethylene | 400D/60 | 37.5mm | Brown | |

0203 | Polyethylene | 400D/60 | 40mm | ||

0186 | Polyethylene | 400D/44 | 100mm | ||

0187 | Polyethylene | 400D/44 | 100mm | Brown | |

0226 | Polyethylene | 400D/44 | 100mm | White | |

0184 | Polyethylene | 400D/44 | 100mm | Black | |

0210 | Polyethylene | 400D/60 | 100mm | ||

0211 | Polyethylene | 400D/60 | 100mm | Silver | |

0215 | Polyethylene | 400D/90 | 37.5mm | ||

0216 | Polyethylene | 400D/90 | 40mm | ||

0217 | Polyethylene | 400D/90 | 40mm | Silver | |

0222 | Polyethylene | 400D/120 | 40mm | ||

0220 | Polyethylene | 400D180 book | 40mm | ||

0786 | Polyethylene | 400D/30 | 15mm | A label is with incombustibility | |

0661 | Polyethylene | 400D/30 | 15mm | Silver | A label is with incombustibility |

0143 | Polyethylene | 400D/36 | 25mm | A label is with incombustibility | |

0145 | Polyethylene | 400D/36 | 25mm | Silver | A label is with incombustibility |

0185 | Polyethylene | 400D/44 | 37.5mm | A label is with incombustibility | |

0175 | Polyethylene | 400D/44 | 37.5mm | Silver | A label is with incombustibility |

0197 | Polyethylene | 400D/50 | 40mm | A label is with incombustibility | |

0640 | Polyethylene | 400D/50 | 40mm | Silver | A label is with incombustibility |

0297 | Polyethylene | 400D/44 | 100mm | A label is with incombustibility | |

0296 | Polyethylene | 400D/44 | 100mm | Silver | A label is with incombustibility |

0240 | Polyethylene | 400D/40 | 25mm | Silver | A label is with incombustibility |

0300 | Polyethylene | 400D/40 | 25mm | Black | A label is with incombustibility |

0659 | Polyethylene | 400D/40 | 37.5mm | Silver | A label is with incombustibility |

0783 | Polyethylene | 400D/40 | 37.5mm | Black | A label is with incombustibility |

●Archery net

Product cord | Fiber name | Thickness of the thread | Scale of mesh | Color | Remarks |

0037 | Polyester | 210D/30 in earnest | 3.9*2.9mm | ||

0038 | Polyester | 210D/30 in earnest | 3.9*2.9mm | Silver | |

0036 | Polyester | 210D/60 in earnest |

●Golf net 1

Product cord | Fiber name | Thickness of the thread | Scale of mesh | Color | Remarks |

0009 | Nylon | 210D/48 | 25mm | ||

0010 | Nylon | 210D/48 | 25mm | White | |

0011 | Nylon | 210D/48 | 25mm | Silver | |

0097 | Polyethylene | 400D/20 | 10mm | ||

0100 | Polyethylene | 350D/20 | 25mm | Natural | |

0106 | Polyethylene | 400D/22 | 25mm | ||

0109 | Polyethylene | 400D/22 | 25mm | Silver | |

0119 | Polyethylene | 400D/24 | 25mm | Brown | |

0124 | Polyethylene | 400D/30 | 25mm | Existence is constipated | |

0135 | Polyethylene | 400D/30 | 25mm | Yellow | |

0125 | Polyethylene | 400D/32 | 15mm | ||

0126 | Polyethylene | 400D/32 | 15mm | Silver | |

0618 | Polyethylene | 400D/32 | 15mm | Brown | |

0127 | Polyethylene | 400D/32 | 20mm | ||

0637 | Polyethylene | 400D/32 | 20mm | Silver | |

0133 | Polyethylene | 600D/18 | 25mm | Powerful thread | |

0144 | Polyethylene | 400D/36 | 25mm | ||

0147 | Polyethylene | 400D/36 | 25mm | Brown | |

0149 | Polyethylene | 400D/36 | 25mm | Silver | |

0150 | Polyethylene | 400D/36 | 25mm | Black | |

| 0151 | Polyethylene | 400D/36 | 25mm | White | |

0153 | Polyethylene | 400D/36 | 25mm | Blue | |

0156 | Polyethylene | 400D/36 | 25mm | Orange | |

0160 | Polyethylene | 400D/44 | 25mm | ||

0162 | Polyethylene | 400D/44 | 25mm | Silver | |

0169 | Polyethylene | 400D/50 | 25mm | Silver | |

0166 | Polyethylene | 400D/60 | 25mm | ||

0786 | Polyethylene | 400D/30 | 15mm | A label is with incombustibility | |

0661 | Polyethylene | 400D/30 | 15mm | Silver | A label is with incombustibility |

0143 | Polyethylene | 400D/36 | 25mm | A label is with incombustibility | |

0145 | Polyethylene | 400D/36 | 25mm | Silver | A label is with incombustibility |

0240 | Polyethylene | 400D/40 | 25mm | Silver | A label is with incombustibility |

0300 | Polyethylene | 400D/40 | 25mm | Black | A label is with incombustibility |

●Bird-proof net 1

Product cord | Fiber name | Thickness of the thread | Scale of mesh | Color | Remarks |

0001 | Polyester | 250D/20 | 10mm | ||

0005 | Polyester | 250D/30 | 15mm | ||

0241 | Polyester | 2000T/5 book | 25mm | A label is with incombustibility | |

0264 | Polyester | 2000T/5 book | 25mm | Gray | A label is with incombustibility |

0009 | Nylon | 210D/48 | 25mm | ||

0010 | Nylon | 210D/48 | 25mm | White | |

0011 | Nylon | 210D/48 | 25mm | Silver | |

0280 | Nylon | 14 | 30mm | Transparence | |

0287 | Nylon | 14 | 45.5mm | Transparence | |

0660 | Polyethylene | 2750T/1 book | 15mm | Black | Existence is constipated |

0662 | Polyethylene | 2750T/1 book | 20mm | Black | Existence is constipated |

0672 | Polyethylene | 2750T/1 book | 30mm | Black | Existence is constipated |

0667 | Polyethylene | 2750T/1 book | 40mm | Black | Existence is constipated |

0094 | Polyethylene | 400D/12 | 20mm | Black | Existence is constipated |

0093 | Polyethylene | 400D/12 | 30mm | Black | Existence is constipated |

0092 | Polyethylene | 400D/12 | 50mm | Black | Existence is constipated |

0105 | Polyethylene | 400D/12 | 100mm | Black | Existence is constipated |

0097 | Polyethylene | 400D/20 | 10mm | ||

0095 | Polyethylene | 400D/20 | 10mm | Brown | |

0096 | Polyethylene | 400D/20 | 10mm | Silver | |

0100 | Polyethylene | 350D/20 | 25mm | Natural | |

0106 | Polyethylene | 400D/22 | 25mm | ||

0109 | Polyethylene | 400D/22 | 25mm | Silver | |

0119 | Polyethylene | 400D/24 | 25mm | Brown | |

0121 | Polyethylene | 400D/24 | 25mm | Black | |

0116 | Polyethylene | 400D/22 | 37.5mm | ||

0117 | Polyethylene | 400D/22 | 37.5mm | Silver | |

0665 | Polyethylene | 400D/24 | 15mm | Dark green gray konnen | |

0784 | Polyethylene | 400D/24 | 25mm | Dark green gray konnen | |

0785 | Polyethylene | 400D/24 | 30mm | Dark green gray konnen | |

0135 | Polyethylene | 400D/30 | 25mm | Yellow | |

0102 | Polyethylene | 400D/30 | 15mm | White | |

0125 | Polyethylene | 400D/32 | 15mm | ||

0126 | Polyethylene | 400D/32 | 15mm | Silver | |

0618 | Polyethylene | 400D/32 | 15mm | Brown | |

0127 | Polyethylene | 400D/32 | 20mm | ||

0637 | Polyethylene | 400D/32 | 20mm | Silver | |

0144 | Polyethylene | 400D/36 | 25mm | ||

0147 | Polyethylene | 400D/36 | 25mm | Brown |

Product cord | Fiber name | Thickness of the thread | Scale of mesh | Color | Remarks |

0149 | Polyethylene | 400D/36 | 25mm | Silver | |

0150 | Polyethylene | 400D/36 | 25mm | Black | |

0151 | Polyethylene | 400D/36 | 25mm | White | |

0786 | Polyethylene | 400D/30 | 15mm | A label is with incombustibility | |

0661 | Polyethylene | 400D/30 | 15mm | Silver | A label is with incombustibility |

0143 | Polyethylene | 400D/36 | 25mm | A label is with incombustibility | |

0145 | Polyethylene | 400D/36 | 25mm | Silver | A label is with incombustibility |

0770 | Polypropylene | 760T/11 book | 25mm | White | A label is with incombustibility |

0782 | Polypropylene | 760T/11 book | 25mm | Silver | A label is with incombustibility |

●Storm, erosion control, paint scattering prevention net

Product cord | Fiber name | Thickness of the thread | Scale of mesh | Color | Remarks |

0037 | Polyester | 210D/30 in earnest | 3.9*2.9mm | ||

0038 | Polyester | 210D/30 in earnest | 3.9*2.9mm | Silver | |

0036 | Polyester | 210D/60 in earnest | |||

0255 | Polyester | 5101 | |||

0257 | Polyester | Disaster prevention mesh | A label is with incombustibility | ||

0265 | Polyester | ER-110 | |||

0246 | Polyethylene | Storm network | 1mm | White | |

0247 | Polyethylene | Storm network | 1mm | Black | |

0248 | Polyethylene | Storm network | 1mm | Silver | |

0249 | Polyethylene | Storm network | 1mm | Brown | |

0250 | Polyethylene | Storm network | 1mm | Green | |

0251 | Polyethylene | Storm network | 1mm | Moss-green | |

0252 | Polyethylene | Storm network | 1mm | Blue | |

0253 | Polyethylene | Storm network | 2mm | Green | |

0254 | Polyethylene | Storm network | 4mm | Green | |

0259 | Scattering prevention net | 1mm | Green | A label is with incombustibility | |

0291 | Scattering prevention net | 1mm | White | A label is with incombustibility |

●Slope net

Product cord | Fiber name | Thickness of the thread | Scale of mesh | Color | Remarks |

0006 | Nylon | 210D/nine | 17mm | Existence is constipated; hishimoku | |

0030 | Polyester | 2000D/five | 30mm | ||

0118 | Polyethylene | 400D/22 | 37.5mm | GG | hishimoku |

0178 | Polyethylene | 400D/44 | 30mm | GG | hishimoku |

0180 | Polyethylene | 400D/44 | 37.5mm | GG | hishimoku |

●Safety net

Product cord | Fiber name | Thickness of the thread | Scale of mesh | Color | Remarks |

0016 | Nylon | 210D/162 | 50mm | White | Existence is constipated; hishimoku Temporary construction industry authorization |

0017 | Polyester | 250D/162 | 100mm | White | Existence is constipated; hishimoku |

0021 | Nylon | 210D/306 | 50mm | White | Existence is constipated; hishimoku |

0022 | Nylon | 210D/306 | 100mm | White | Existence is constipated; hishimoku Temporary construction industry authorization |

0039 | Polyester | 250D/46 | 15mm | White | hishimoku Temporary construction industry authorization |

0046 | Polyester | 250D/46 | 15mm | Eco, hishimoku Temporary construction industry authorization | |

0267 | Polyester | 250D/56 | 18mm | Blue | Incombustibility, hishimoku Temporary construction industry authorization It is with a label |

●Good self-care, exfoliation protection net

Product cord | Fiber name | Thickness of the thread | Scale of mesh | Color | Remarks |

0001 | Polyester | 250D/20 | 10mm | hishimoku | |

0003 | Polyester | 210D/ten | 15mm | hishimoku | |

0005 | Polyester | 250D/30 | 15mm | hishimoku | |

0043 | Polyester | 2200T/5 book | 10mm | Incombustibility | |

0045 | Polyester | 2000T/5 book | 10mm | Gray | Incombustibility |

0029 | Polyester | 2000T/5 book | 15mm | A label is with incombustibility | |

0611 | Polyester | 2000T/5 book | 15mm | Gray | A label is with incombustibility |

0616 | Polyester | 2000T/5 book | 15mm | Blue | A label is with incombustibility |

0238 | Polyester | 1670T/10 book | 10mm | Black | Incombustibility |

0606 | Polyester | 280T/30 book | 15mm | Black | Incombustibility |

0006 | Nylon | 210D/nine | 17mm | Existence is constipated; hishimoku | |

0040 | Polyester | 2000D/five | 25mm | ||

0030 | Polyester | 2000D/five | 30mm |