Wire Cloth for the vibration sieve

●I produce all on an assembly line from finer particles, the one for ore to the one for food from a large lump particle.

●Type of the Wire Cloth

The Wire Cloth to use becomes the following.

●I recommend the Wire Cloth for the vibration sieve so that the most suitable thing is chosen from the following type mainly by the big things and small things of the sorting object, the type of a work load, the machine.

●Please feel free to contact me if you can show me the details such as use uses as you suggest it from us.

Type of the Wire Cloth | Materials | |

Corner eyes | ・Overall stainless steel steel wire

・Hard steel wire (SWRH42B, SWRH62A)

・Iron wire

・Others | |

Longish | ||

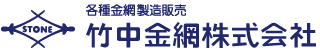

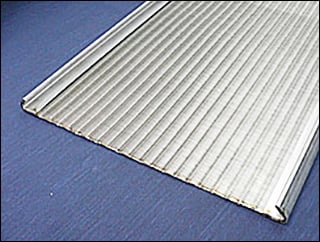

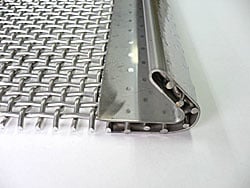

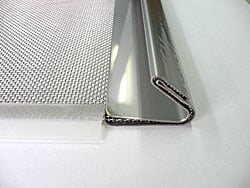

●Tension hook of the Wire Cloth

The Wire Cloth used in a vibration sieve processes a hook into both sides and has the next effect.

・It is easy to put on and take off it to a sieve machine.

・I strengthen the relationship of the sieve network.

・I give a sieve network tension and prevent a sauce falling.

The Wire Cloth used in a vibration sieve processes a hook into both sides and has the next effect.

・It is easy to put on and take off it to a sieve machine.

・I strengthen the relationship of the sieve network.

・I give a sieve network tension and prevent a sauce falling.

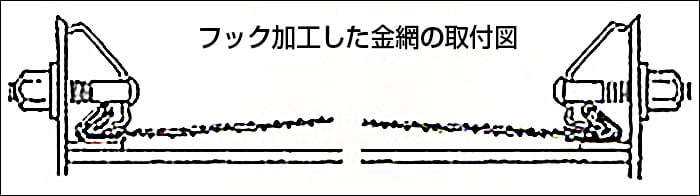

●Dimensions of the vibration sieve Wire Cloth

Width of the W = sieve network ※Dimensions out of the hook, dimensions instructions in the hook

Length of the L = sieve network

The length of the L1 = hook

Part without the L2 = hook ※Stack charges of the Wire Cloth, normal around 20mm

Width of the W = sieve network ※Dimensions out of the hook, dimensions instructions in the hook

Length of the L = sieve network

The length of the L1 = hook

Part without the L2 = hook ※Stack charges of the Wire Cloth, normal around 20mm

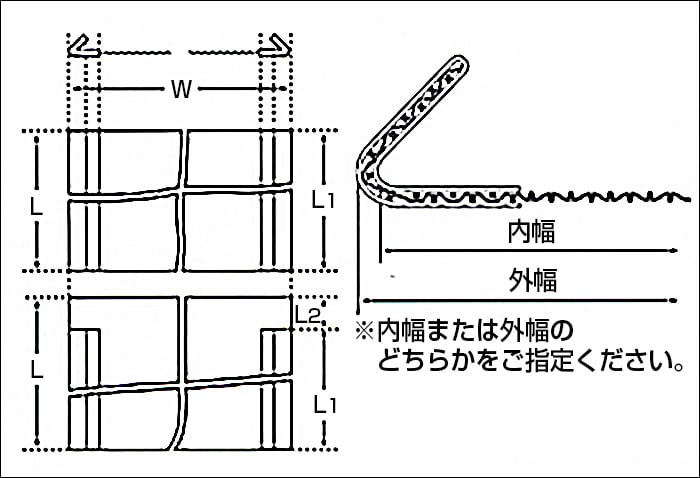

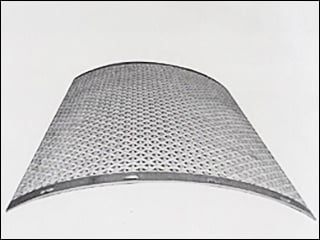

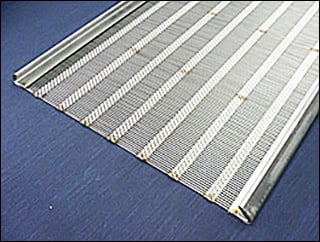

●A flow direction and halftone plate direction of the processing thing

The following halftone plates are the rectangular Wire Cloth in a halftone plate direction (slot) for the flow direction of the processing thing.

・Ton cap Wire Cloth

・Tie rod Wire Cloth

A type and example of the Wire Cloth for the sieve

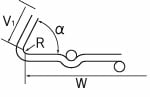

Type of the tension hook

Figure | Name | Materials |

Wire Cloth | ・Stainless steel steel wire ・Galvanizing iron wire ・Hard steel wire | |

Our t1 board

(steel sheet) | ・SS (iron) (SPCC, bonderizing steel sheet)

・Stainless steel (SUS304, SUS316L, SUSU430) | |

t2 rubber board (t 0.8mm) (t 1.0mm) (t 1.5mm) | ・Natural rubber (NR) ・Neoprene rubber (CR) ・Nitrile rubber (NBR) ・Silicone gum (SR) ・Ethylene propylene rubber (EPDM) ・In addition, it is chosen by a use use |

Tension hook standard specifications

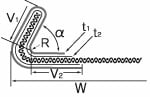

Type | Style of the hook | Dimensions of all parts | Summary | |||

No. 1 |  | V1 | 30 | V2 | When it is line diameter Φ 6.0mm or more, I use it | |

α | 60 degrees | R | 6 or more | |||

t1 | - | t2 | - | |||

| ||||||

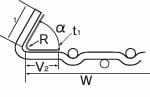

No. 2 |  | V1 | 25 | V2 | (25-30) | When it is line diameter Φ 4.0mm or more, I use it and am belonging to our board (t1) |

α | 60 degrees | R | 6 | |||

t1 | SS3.2 SS2.3 SUS3.0 | t2 | - | |||

| ||||||

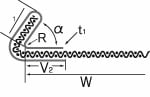

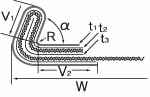

No. 3 |  | V1 | 25 | V2 | (25-30) | In the case of less than Φ 6.0mm, I use it line diameter Φ 1.0mm or more and am belonging to our board (t1) ※The rivet stopper is manufacturable, too ※The spot end is manufacturable, too |

α | 45 degrees | R | 3 | |||

t1 | 1-1.6 | t2 | - | |||

| ||||||

No. 4 |  | V1 | 25 | V2 | (25-30) | In the case of less than Φ 1.0mm, I use it line diameter Φ 0.5mm or more and am belonging to our board (t1) and rubber board (t2) ※The rivet stopper is manufacturable, too |

α | 45 degrees | R | 3 | |||

t1 | 1-1.6 | t2 | 1 | |||

| ||||||

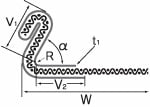

No. 5 |  | V1 | 25 | V2 | (25-30) | In the case of less than line diameter Φ 1.0mm, I use it and am belonging to our board (t1) and rubber board (t2) ※The rivet stopper is manufacturable, too ※Rubber roll production is possible in (t3) |

α | 45 degrees | R | 3 | |||

t1 | 1 | t2 | 1 | |||

t3 | 0.3-1 | |||||

| ||||||

No. 6 |  | V1 | 25 | V2 | (25-30) | In the case of less than line diameter Φ 1.6mm, I use it and am belonging to our board (t1) ※The spot end is manufacturable, too |

α | 30 degrees | R | 3 | |||

t1 | 0.8 | t2 | ||||

| ||||||

Sieve additional processing

※I perform the following processing, processing depending on a request.

Please feel free to contact me.

・Welding stopping processing

・I process it in reply

・Welding stopping processing

・I process it in reply

・Rivet processing

・Silicon coating processing

・Silicon rubber processing

・Silicon coating processing

・Silicon rubber processing

・Multiplex tension sieve processing