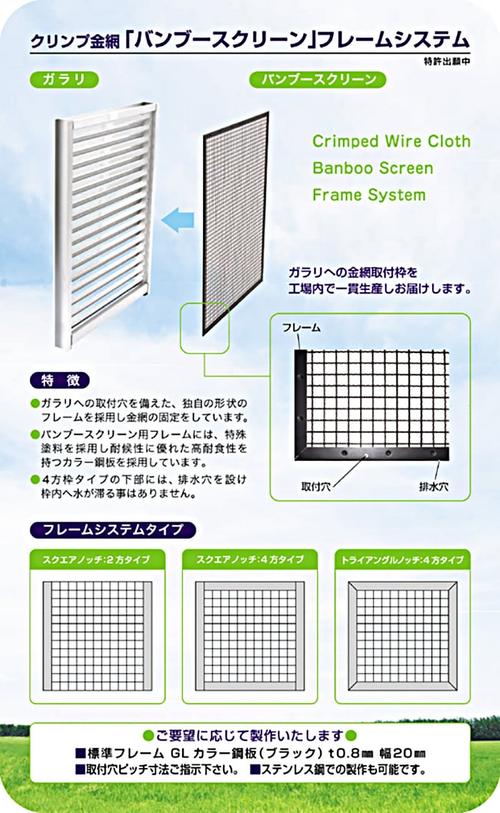

Bird-proof Wire Cloth

Crimp Wire Cloth Bamboo screen

●I aimed at the non-dioxin and got rid of VOC-rich air blast painting work without using a chemical substance suspected of the environmental endocrine disrupter.

I reduce paint consumption in comparison with the air blast painting for the conventional Wire Cloth by approximately 80%.

I reduce paint consumption in comparison with the air blast painting for the conventional Wire Cloth by approximately 80%.

I greatly nominate an effect for emission abatement of carbon dioxide (CO2) in the paint process of manufacture and do not neglect the consideration to the human body and natural environments.

It is "the eco-measures product" which is kind to both people and nature.

Environmental characteristic

Influence on health of the worker is reduced because I paint Depp firing in the factory in-line without performing the blowing painting that used conventional VOC [※ 1] abundantly and a large quantity exhausts VOC in the atmosphere and may not let you scatter.

I reduce paint consumption about 80% in comparison with the blowing painting for the conventional Wire Cloth and greatly achieve an effect for emission abatement [※ 2] of carbon dioxide (CO2) in the paint process of manufacture.

I adopt special resin of non-vinyl chloride which aimed at the non-dioxin and do not use a chemical substance (Ministry of the Environment 67 material) suspected of the environmental endocrine disrupter and do not neglect consideration to environment.

Furthermore, it is "the eco-measures product" which is kind to the earth as material recycle is the material which is easy to do it after having used it for a long term.

[※ 1] Volatile organic compounds (VOC:volatile organic compounds)

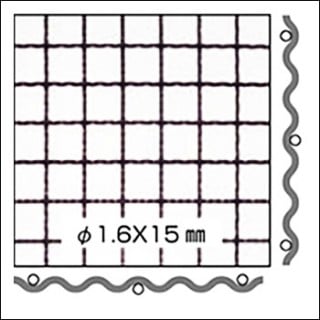

[※ 2] φ1.6X15 mm eyes Wire Cloth: Comparison between blowing painting (about 17μm) and Bamboo screen (about 26μm)

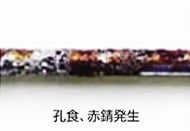

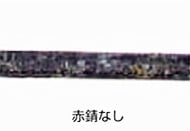

Corrosion resistance, weatherability

In a crimp Wire Cloth wire, I adopted the wire which I developed originally and realized superior corrosion resistance, weatherability.

Zinc - aluminum alloy plating line of the core line is used as superior engineering works material of corrosion resistance, the durability widely now, and it is recognized as the thing which finds 30 years in the Ministry of Land, Infrastructure, Transport and Tourism for service life in the fresh water.

Furthermore, on the surface of the wire, you can use special resin paint in peace in the severe environment as the firing painting usually puts the film thickness that is double the firing painting film thickness (about 26μm or more).

In addition, the section of the wire edge controls an expanse of the rust by the sacrifice prevention of rust action that a wire has.

Superior economy

The price merit that is larger than coating equipment is shown after the product made in conventional stainless steel crimp Wire Cloth by using the wire which prints the zinc - aluminum alloy plating + special polyester resin which I developed originally, and gave the painting.

※It is the comparison with our conventional dimensions cut product.

※A price difference may not have it by the delivery place, amount, dimensions.

※There is the change of the price difference by materials price market price.

※There is the change of the price difference by materials price market price.

A variety of measuring characteristics and short deadline

Product dimensions do not depend on the dimensions limit of the painting booth, the firing furnace with conventional firing painting specifications because it produces crimp Wire Cloth using the wire which colors it before processing, and was painted.

As for the crimp Wire Cloth, as for the dimensions restrictions such as the welding Wire Cloth, there are none.

As there is not the painting process after the Wire Cloth product completion, the delivery on the short deadline is possible.

Specifications (※ standard color becomes the black)

Line diameter Diameter(mm) | Difference eyes Opening(mm) | Opening rate Aperture Ratio |

Φ 1.6 | 8.0 | 69.44% |

Φ 1.6 | 10.0 | 74.32% |

Φ 1.6 | 12.0 | 77.85% |

Φ 1.6 | 15.0 | 81.65% |

Φ 1.6 | 20.0 | 85.73% |

Φ 2.6 | 15.0 | 72.64% |

Φ 2.6 | 25.0 | 82.05% |

Φ 2.6 | 30.0 | 84.69% |

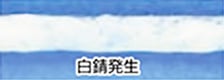

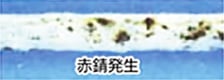

●Salt water mist examination

Examination time

| Examination sample

| |

I print a special polyester resin and paint it

Zn-Al alloy plating iron wire

(Φ 3.2 dark brown)

| Three kinds of galvanizing iron wire

(SWMCGSΦ3.2)

| |

0 hours

|  |  |

200 hours

|  |  |

500 hours

|  |  |

1,000 hours

|  |  |

●Seawater dipping test [an examination place: Fisheries Lab. of Kinki Univ. Shirahama test site]

Period

| Sample

| |

Zinc -10% aluminum alloy plating iron wire

(Φ 4.0mm)

(AI: a quantity of 10% plating adhesion: 380 g/square meter)

| Stainless steel copper wire

(SUS304 W1Φ4.0mm)

| |

1,112 days later

(about three years)

|  |  |

1,762 days later

(about five years)

|  |  |

Residual plating adhesion quantity 173 g/㎡

| -

| |

※In the environment where there is damage from salt breeze environment, chlorine, zinc - aluminum alloy plating iron wire has corrosion resistance superior to stainless steel steel wire.

●Salt water mist examination [an examination place: Nichia Steel Works,Ltd.] of the Bamboo screen

Time

| Point

| ||

Metal central part

| Expansion

| Edge

| |

0 hours

|  |  |  |

240 hours

|  |  |  |

500 hours

|  |  |  |

3,000 hours

|  |  |  |

・The white product which occurred on the Bamboo screen surface gradually spreads. But the outbreak of the rust does not happen in the long-time examination called 3,000 hours either.

・In the edge that I cut with pliers, rust occurs just a little bit partially, but the expanse of the rust does not happen.

・In the edge that I cut with pliers, rust occurs just a little bit partially, but the expanse of the rust does not happen.

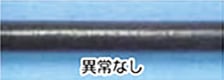

[about the antirust effects of the edge]

●Consideration about the sacrifice prevention of rust mechanism

Zinc is the metal which is easy to ionize than iron (is easy to be oxidized, and is easy to melt).

●Consideration about the sacrifice prevention of rust mechanism

Zinc is the metal which is easy to ionize than iron (is easy to be oxidized, and is easy to melt).

I am oxidized immediately, and iron produces rust in the natural world, but iron is oxidized and may not produce rust because zinc which is easy to ionize melts earlier when I exist with zinc.

I call this mechanism sacrifice prevention of rust mechanism that zinc oneself is sacrificed and protects iron.

In this salt water mist examination, this mechanism was formed of the section of the Bamboo screen, and the big change did not get up in the point where basis material iron was exposed by a sacrifice prevention of rust effect of zinc either.

The rust occurred just a little bit, but thinks that it does not extremely progress after this.

As it is put together in the Wire Cloth of the type that I gave strongly each other, the halftone plate is maintained exactly definitely.

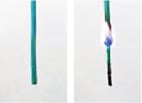

●Combustibleness [lead direct methane burner examination]

Product name

| Special polyester resin

Firing painting plating iron wire

(SWMCGS-3Φ3.2 dark brown)

| Vinyl chloride covered wire

(SWMV-GS3 32-23 green)

| Polyethylene covered wire

(SWME-GS3 32-23 green)

|

The appearance before and after examination

|  |  |  |

Degree of the expanse of the combustion

| Unavailable

| Carbonization distance: 30mm

| ∞

|

Lingering force time

| Unavailable

| ∞

| |

State

| Flaming retardant

There is no change

| I fired it once and extinguished a fire naturally. The heating part changed while being accompanied by a bad smell, and a heart line was exposed.

| I fired it, and coating melted, and a heart line was exposed. I continue catching fire unless I extinguish a fire forcibly.

|

※I may not burn because it is heat-resistant and uses superior special resin paint.

※The expanse of the combustion was not confirmed in the lead direct methane burner examination (based on the A-4 method of JIS L 1091).

※The expanse of the combustion was not confirmed in the lead direct methane burner examination (based on the A-4 method of JIS L 1091).