Sintering Wire Cloth

●abusoruta

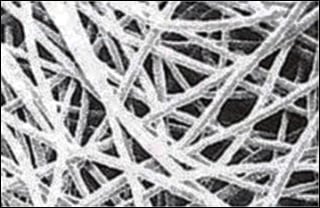

I put many Wire Cloth made of stainless steel on top of one another and repeat processing, sintering and am the board form noro materials which let contact region of the metal wire have *chaku.

I form the new three-dimensional filtration hole which I follow it, and metal wire overlapping by plastic deformation divides the hole in a halftone plate each other and is minute and bent complicatedly.

The size of the ro hole is fixed by mesh, the lamination number of Wire Cloth, a pressurization power at the time of the sintering.

●poametto

It is sisters product of abusoruta.

poametto laminates five levels of Wire Cloth made of stainless steel and is sintering shitaro materials.

The size of the ro hole is decided in the second level Wire Cloth, and the fourth level and the fifth level offer enough strength by to use a tough tatami mat texture for reinforcement use, do not need the new reinforcement such as punching materials.

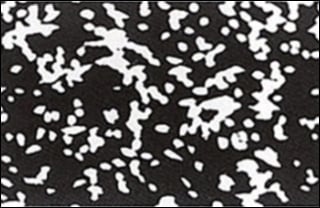

●poafuro

With the multi-hole board which lowers an existence hole degree, and raised gas resistance, it is used for the field except the filtration, e.g., particulate matter transportation, foaming, sweat, resistance.

I show a superior filtration system to have of the Wire Cloth enough.

・Filtration resistance

ji tsuro hole of the Wire Cloth is smooth, and the resistance for the fluid is extremely small.

・Pressure tightness

With strength and tenacity peculiar to stainless steel, I further have structurally superior pressure tightness by sintering.

・Heat-resistant

With heat-resistant strength and oxidation resistance of the stainless steel, I can use it in -269 degrees Celsius - 600 degrees Celsius of oxidative atmosphere.

・Corrosion resistance

I reproduce corrosion resistance peculiar to stainless steel.

・Effect to backwash

The reproduction effect by backwashing it is high and endures long-term use.

・Others

These elements with the characteristic mentioned above are extremely superior in economy and enable the design of the compact housing.

Use

It is for filtration | Industrial oil, fuel oil, edible oil, food, chemicals such as the juice, high polymer polymers, pure water, waste water, air, gas, the filtration of every fluid, the filtration use of the analytical instrument. |

Use to dehydrate | Sludge dehydration, de-oil, dehydration of the food process of manufacture. |

The one for support | The filmy supports such as reverse osmotic membranes, a support of the kei so soil filtration. |

An inquiry form is this

I look forward to the inquiry over the telephone.

Stainless steel fiber filter

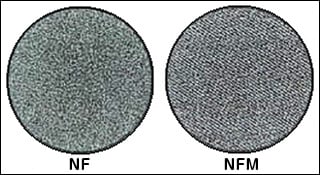

nasuronfiruta (fine pore)

●Characteristic

・It is bigger with 60-80% of cavity rates than metal ro materials of permeability et al., and a pressure loss is full of it, and small efficient filtration is possible.

・By stainless steel fiber and the number of the steps effect of the filtration precision micron order, I show high filtration precision.

・Of the stability stainless steel fiber of the media is mutual, and a junction is sintered strongly, and is the stable media where eyes difference, detachment cry.

・The ability for alien substance maintenance is several times in comparison with ability for alien substance maintenance Wire Cloth, the metal powdery sintering media. With the thing of the same filtration precision, life that being all gets longer.

・A barotolerant material is metal fiber of the micron order, but I am sintered strongly and have superior pressure tightness by appropriate reinforcement.

・I have superior heat resistance, corrosion resistance to have of heat resistance, the corrosion resistance stainless steel (SUS 316 L).

・It is physical and the adoption of various reproduction methods is possible and, by a characteristic of the reproduction-related stainless steel, comes by long-term repeated use chemically.

・Cutting, a fold charge account, welding processing are possible structurally, and, with the features such as the taosei filtration precision of specifications, the pressure loss small, the capacity to resist pressure size, a shape can cope with a wide use.

・Of the stability stainless steel fiber of the media is mutual, and a junction is sintered strongly, and is the stable media where eyes difference, detachment cry.

・The ability for alien substance maintenance is several times in comparison with ability for alien substance maintenance Wire Cloth, the metal powdery sintering media. With the thing of the same filtration precision, life that being all gets longer.

・A barotolerant material is metal fiber of the micron order, but I am sintered strongly and have superior pressure tightness by appropriate reinforcement.

・I have superior heat resistance, corrosion resistance to have of heat resistance, the corrosion resistance stainless steel (SUS 316 L).

・It is physical and the adoption of various reproduction methods is possible and, by a characteristic of the reproduction-related stainless steel, comes by long-term repeated use chemically.

・Cutting, a fold charge account, welding processing are possible structurally, and, with the features such as the taosei filtration precision of specifications, the pressure loss small, the capacity to resist pressure size, a shape can cope with a wide use.

●Use

The production of the adapted thing is possible by the purposes of use such as the things which I turned NFM type, expression of the eye, the constitution that reinforced high polymer industry, chemical industry, Yakuhin Kogyo, painting line, powders plant, oil pressure, air pressure apparatus, measurement, instrumentation apparatus, other both sides, one side with metal into.

Fine pore NF standard specifications

Name | ※1

Filtration precision

μm | ※2 Valve point pressure Pa | Transmission flow rate | ||

※3 air l/cm2/mi | ※4 water cc/cm2/mi | ※5 high viscosity liquids cc/cm2/min | |||

NF-03 | 3 | 9,560 | 0.15 | 18 | 0.083 |

NF-05 | 5 | 6,950 | 0.32 | 38 | 0.20 |

NF-06 | 10 | 3,600 | 1.1 | 140 | 1.2 |

NF-07 | 15 | 2,730 | 1.8 | 200 | 1.7 |

NF-08 | 20 | 2,250 | 2.4 | 300 | 2.3 |

NF-09 | 25 | 1,790 | 3.2 | 400 | 3.0 |

NF-10 | 30 | 1,410 | 5.0 | 600 | 4.5 |

NF-12 | 40 | 1,120 | 6.4 | 750 | 6.0 |

NF-13 | 60 | 830 | 9.2 | 1000 | 8.7 |

NF-14 | 80 | 460 | 15.0 | 1500 | 12.0 |

[note]

※The standard examination powders's greatest particle size which penetrated the filter media by a method of JSB-8356 1.

※Air pressure and the air pressure, examination liquid by the going pore size examination of JISB-9356 of the intersection of the flow rate graph use isopropyl alcohol 2. Temperature 25 degrees Celsius.

※Transmission flow rate in differential pressure 294Pa of 3:25 ℃ atmosphere.

※Transmission flow rate in differential pressure 1,960Pa of 4:25 ℃ water.

※It is transmission flow rate in differential pressure 4.9MPa of the 2000Poise fluid 5.

※The standard examination powders's greatest particle size which penetrated the filter media by a method of JSB-8356 1.

※Air pressure and the air pressure, examination liquid by the going pore size examination of JISB-9356 of the intersection of the flow rate graph use isopropyl alcohol 2. Temperature 25 degrees Celsius.

※Transmission flow rate in differential pressure 294Pa of 3:25 ℃ atmosphere.

※Transmission flow rate in differential pressure 1,960Pa of 4:25 ℃ water.

※It is transmission flow rate in differential pressure 4.9MPa of the 2000Poise fluid 5.

※There is an exclusive catalogue.